In an era where sustainability and environmental responsibility are at the forefront of construction practices, precast concrete stands out as a building material that aligns seamlessly with these values. With its versatility, durability, and efficiency, precast concrete offers a myriad of environmental benefits that not only reduce the carbon footprint but also contribute to the overall well-being of our planet. In this comprehensive blog post, we will delve into the environmental advantages of using precast concrete in construction, exploring how it conserves resources, minimizes waste, and promotes long-term sustainability.

Before we delve into the environmental benefits, let’s briefly understand what precast concrete is and how it differs from conventional concrete.

Precast Concrete is a construction material produced by casting concrete in a reusable mold or “form” that is then cured in a controlled environment. Once the concrete has reached its desired strength, it is transported to the construction site and lifted into place. This method contrasts with the traditional cast-in-place concrete, which is poured and cured on-site.

Environmental Benefits of Precast Concrete

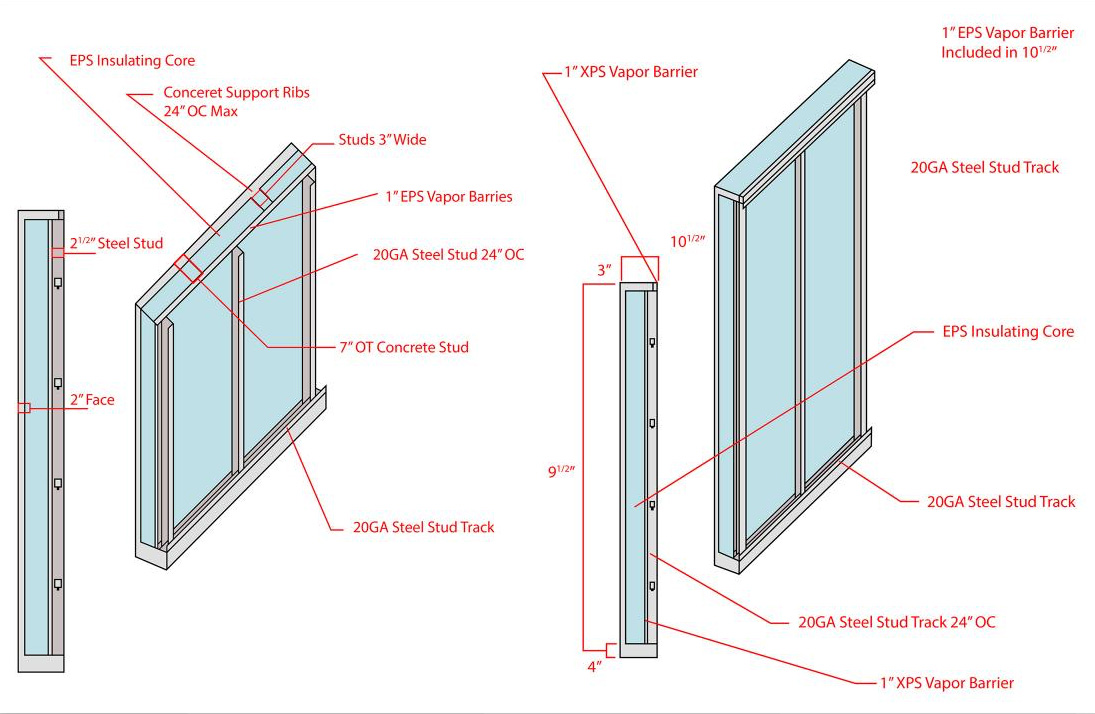

The image used above is an Insulated Concrete Wall System from King Precast. Learn more about the Insulated Concrete Wall System.

1. Reduced Carbon Emissions

One of the most significant environmental benefits of precast concrete is its ability to reduce carbon emissions associated with construction. This reduction occurs through several key avenues:

- Energy Efficiency: Precast concrete manufacturing plants are highly efficient, with precise control over curing conditions. This results in reduced energy consumption compared to on-site concrete production.

- Lower Transportation Emissions: Transporting precast concrete elements to the construction site is more efficient than delivering raw materials and mixing concrete on-site. This reduces the carbon footprint associated with transportation.

- Longer Lifespan: Precast concrete structures tend to have longer lifespans than traditional buildings, meaning less frequent demolition and reconstruction, which can be resource-intensive and emissions-heavy.

2. Resource Conservation

Precast concrete minimizes resource consumption through various means:

- Reduced Material Waste: Precast concrete production generates less waste because it is produced in a controlled environment with precise measurements. Any excess concrete can be recycled, reducing the environmental impact.

- Optimized Material Use: Precast concrete allows for precise control over the amount of material used in construction, reducing overuse and minimizing the extraction of raw materials.

- Sustainable Aggregates: Many precast concrete manufacturers use recycled aggregates in their mixtures, further reducing the demand for virgin resources.

3. Improved Air Quality

Unlike some construction materials, precast concrete does not emit volatile organic compounds (VOCs) or other harmful pollutants into the air. This contributes to better indoor and outdoor air quality, promoting healthier living and working environments.

4. Energy Efficiency in Buildings

The thermal mass properties of precast concrete contribute to energy-efficient buildings. Precast concrete structures can store and release heat, reducing the need for heating and cooling systems. This can lead to lower energy consumption and reduced greenhouse gas emissions over the building’s lifespan.

5. Reduced Maintenance and Demolition

Precast concrete’s durability and resistance to environmental factors such as weather and corrosion mean that buildings and structures made with this material require less maintenance and repair. This not only saves resources but also extends the useful life of the construction, reducing the need for premature demolition and rebuilding.

6. Sustainable Practices in Manufacturing

Many precast concrete manufacturers are adopting sustainable practices within their operations. This includes recycling and reusing water, implementing energy-efficient equipment, and using environmentally friendly concrete mixtures. These efforts further reduce the environmental impact of precast concrete production.

Real-world Applications of Precast Concrete Sustainability

1. Precast Concrete in Sustainable Housing

Precast concrete is an excellent choice for residential housing construction due to its combination of strength, durability, and efficiency. Its exceptional durability ensures that homes built with precast concrete components withstand the test of time, requiring minimal maintenance and reducing long-term costs. Precast concrete’s thermal mass properties contribute to energy-efficient homes, providing better insulation and reducing heating and cooling expenses.

Additionally, precast concrete elements can be manufactured off-site, accelerating construction timelines and minimizing on-site disruptions, making it an ideal choice for meeting the growing demand for sustainable, comfortable, and cost-effective residential housing.

2. Precast Concrete Bridges and Infrastructure

Precast concrete is an ideal choice for bridges and infrastructure projects due to its inherent strength, durability, and versatility. Its robust nature allows it to withstand heavy loads and harsh environmental conditions, ensuring the longevity of critical infrastructure. Precast concrete components can be produced with precision in controlled factory settings, leading to higher quality and consistency compared to on-site casting. This results in faster construction timelines, reduced traffic disruptions, and cost savings.

Additionally, precast concrete’s adaptability enables the creation of complex bridge designs and versatile infrastructure elements, making it an indispensable material for building and maintaining resilient and efficient infrastructure systems.

3. Precast Concrete in Commercial Buildings

Precast concrete is revolutionizing commercial construction by offering unmatched speed, versatility, and sustainability. Its off-site manufacturing allows for rapid project completion, minimizing construction timelines and disruptions in busy commercial areas. Precast elements enable architects to unleash their creativity, resulting in stunning and functional commercial structures. The material’s consistent quality and durability enhance structural integrity and longevity.

Moreover, precast concrete aligns perfectly with sustainability goals, reducing waste, energy consumption, and carbon emissions in a sector increasingly focused on environmental responsibility. As a transformative force in commercial construction, precast concrete not only enhances efficiency but also enables the creation of sustainable, visually appealing, and long-lasting commercial spaces.

Challenges and Future Directions of Precast Concrete

While precast concrete offers numerous environmental advantages, it is essential to acknowledge that challenges exist, such as the energy required for initial manufacturing. However, ongoing research and innovation in materials and production methods aim to address these challenges and further improve the sustainability of precast concrete.

Precast Concrete is the Green Solution For Future Construction

In conclusion, precast concrete is not only a robust and versatile construction material but also a sustainable choice with significant environmental benefits. From reducing carbon emissions and conserving resources to improving air quality and promoting long-term sustainability, precast concrete plays a pivotal role in environmentally responsible construction practices. As the construction industry continues to prioritize sustainability, precast concrete is poised to remain a crucial ally in building a more sustainable future for our planet.